Cast-In Heaters

Cast-In Heater Manufacturer

As a leading cast-in heater manufacturer for the plastic processing industry, MPI Morheat offers thousands of industry-standard designs or can provide customized engineered solutions. Our cast-in products are based on years of expertise, developing these cast-in heater products for a vast array of equipment manufacturers.

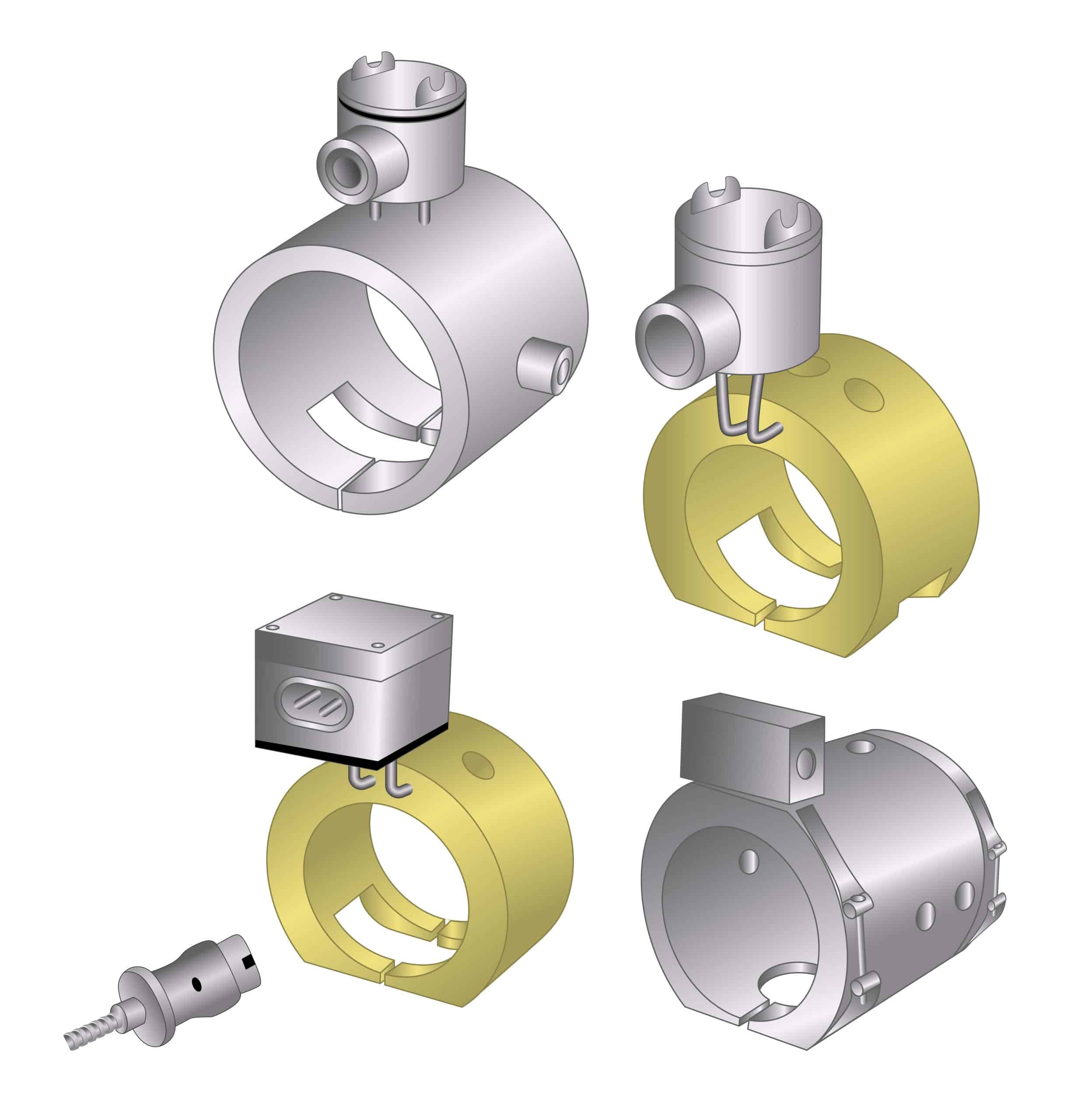

Our electric cast-in heaters are made of aluminum, bronze, or other alloys for various heating applications. Cast-in heaters are used in a variety of industries, including semiconductor and plastics processing, packaging machinery, food service, paper processing, adhesives, medical equipment, heat transfer presses, and textile manufacturing. They are highly efficient and provide precise heating, making them suitable for any industry where this is necessary.

We have design and production capabilities ranging from high-volume cast platen heaters to complex, high-precision heated machine parts with unmatched temperature uniformity. We accomplish this through high vertical integration of virtually all design and production processes.

Cast-In Heater Advantages

Cast-in heaters offer several advantages, primarily their durability, which makes them a desirable choice in almost any environment. In addition, these heaters have the following benefits:

Wide temperature range: Cast-in aluminum heaters can be used for applications up to 700°F (371°C), while cast-in bronze heaters can be used for applications up to 1400°F (769°C).

Customization: Cast-in heaters can be manufactured with complex geometry to suit custom applications. They can be integrated into a machine or process as a functional part, saving space in complex assemblies and efficiently directing heat where it is needed.

Precision: Cast-in heaters can be machined to tight tolerances for precise applications.

Efficient heating: Element layout is optimized to ensure heat is transferred through the working surface for efficient heating.

Uniform heating: Heaters can be designed with multiple elements laid out in separate controlled zones for greater control of the heating process, ensuring uniform heating.

Cast-In Heater Specs

| Cast Materials | Maximum Operating Temperatures |

| Aluminum 443 | 800°F (427°C) |

| Aluminum 319/356 | 700°F (371°C) |

| Bronze / Copper Alloys | 1400°F (769°C) |

| Iron | 900°F (482°C) |