Cast-In Cross Head Die Heater Manufacturer

- Manufacturer

- Always On Time

- Fast, Cheap, and Reliable Shipping

- Quick Response Times (10 minutes or less)

Standard Lead Times

- 4-6 Weeks Manufacturing

- 1-3 days shipping

Extrusion Cross Head and related extrusion dies present extremely

challenging operating parameters to most conventional heating elements.

This is primarily due to the presence of excessive contamination,

high watt densities and high temperature as well as unusual

physical and dimensional requirements.

Many processors continue to use ceramic and mica band heaters on

this application, with frequently marginal results. In these instances,

Cast-In Aluminum or Bronze heaters are recommended to substantially

improve heater life expectancy and performance.

Cast-In Heaters are less susceptible to contamination problems,

and can operate at higher temperatures with higher watt densities.

In addition, the design is structurally better suited to accommodate

holes and cutouts without compromising the heater’s electrical and

mechanical integrity.

As a standard, Cross Head Die Heaters are typically designed in aluminum as a one-piece band with a single slot that

can be slid over the die and clamped with stainless steel clamping straps. For higher temperature or high watt density

requirements, bronze or brass alloys can be used.

– Computer designed, precisely formed tubular heating element, optimizing the heat transfer pattern.

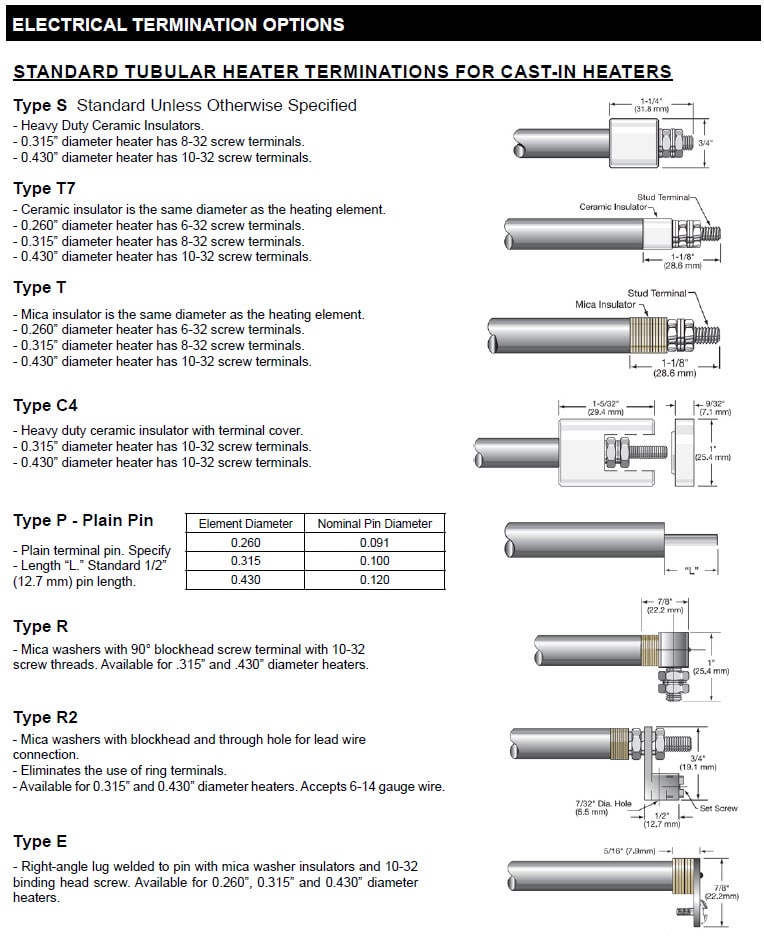

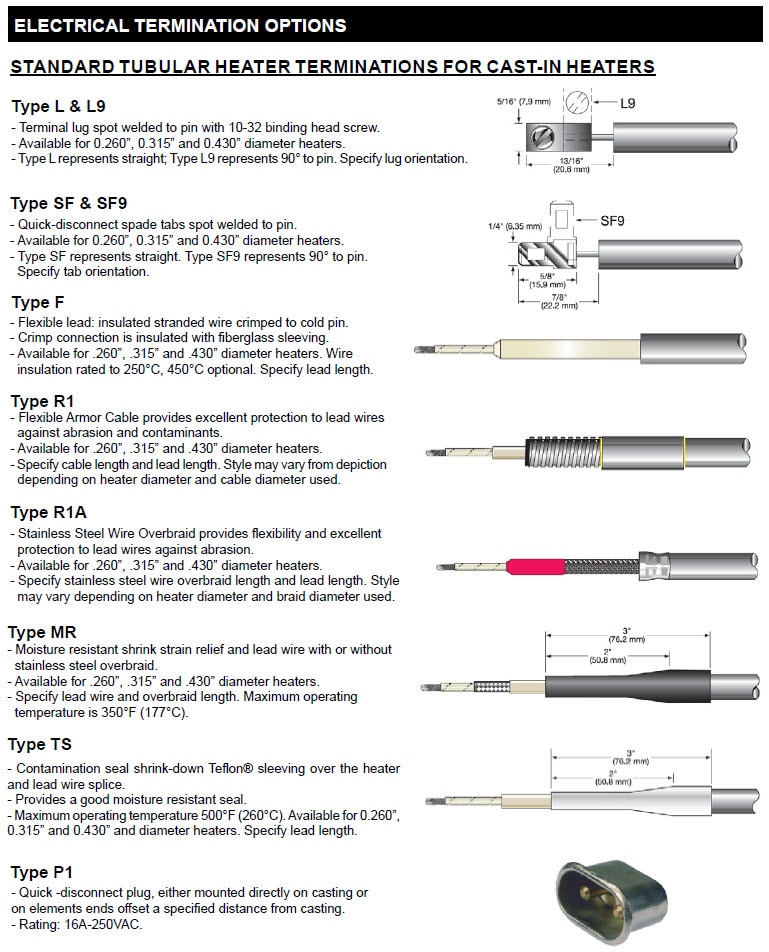

– Variety of termination options, including terminal enclosure housings.

– Optional 1/4”, 3/8” or 1/2” cooling tubes cast into the cross head die body for liquid cool function.

– Variety of shapes and sizes.

– Aluminum and bronze alloys.

– Through holes, tap holes or cutouts to facilitate mounting or obstructions.

– Precision machining of one or all surfaces of casting – specify your individual requirements.

For sizes and ratings not listed, we will design and manufacture a Cross Head Die Heater to meet your requirements.

Specify the following:

– Inside Diameter

– Outside Diameter

– Thickness

– Wattage and Voltage

– Termination Type

– Alloy (Aluminum or Bronze)

– Special Features

– Machining Specifications

– Detailed Drawing