Categories

Hot Melt / Co-Extrusion Heated Hoses

- Manufacturer

- Replacements for all Competitor Models

- Same Day Manufacturing Available

- Always On Time

- Fast, Cheap, and Reliable Shipping

- Quick Response Times (10 minutes or less)

Standard Lead Times

- 3 Weeks Manufacturing

- **Same Day Manufacturing Available**

- 1-3 days shipping

MPI Plastics Industry Heated Hoses are used to transfer molten plastic or thermocplastic materials

from extruders to molds at high temperatures and pressures. These hoses are manufactured

from high temperature and pressure resistant T3 PTFE hoses.

Advantages of using a Heated Hose for a plastics applications are:

• Heated Hoses provide a flexible connection between a plastic extruder and mold

• Simplifies mold changes and maintenance

• Minimizes the thermal expansion and vibration that occurs from heating material\

• Increases process efficiency

Operating Temperature………..250°C

Voltage……………………………….230V AC/DC 50/60Hz

Rated Power…………………………DN8 (140 W/m)

DN10 (160 W/m)

DN12 (200W/m)

DN16 (250 W/m)

DN20 (330 W/m)

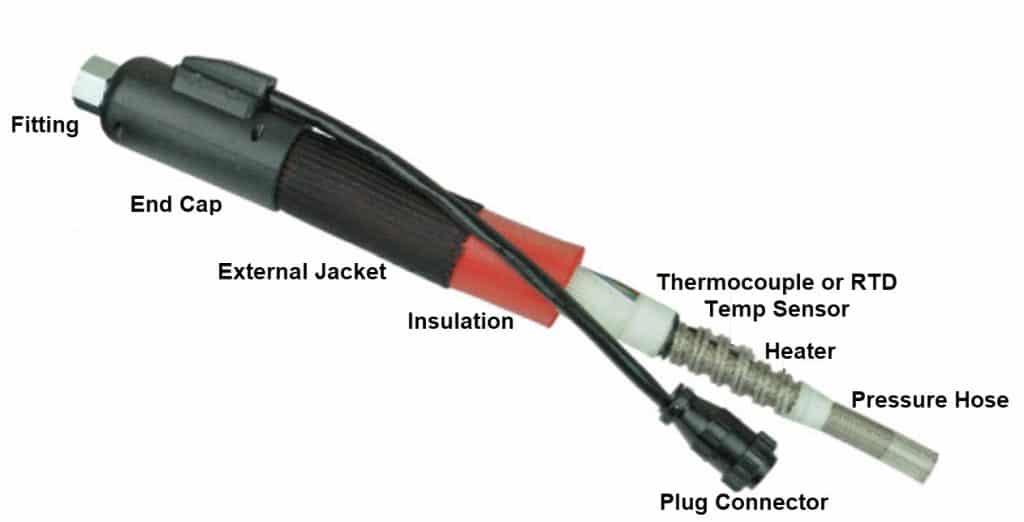

Pressure Hose………………………T3 PTFE

Fittings…………………………………Universal standard UNF , Metric , BSP

Thermical Insulation……………..Silicone Foam

End Cap………………………………..Hard cap

External Jacket……………………..Polyamide Protectice Braid

Power Cable………………………….Standard 2 x 1.5m

Temperature Sensor………………Fe-CuNi (J), PT100, NiCr-Ni (K)

Temperature Limits……………….+5 / -10

| DN | DIameter of Fitting | BDN-M Metric | BDN | Working Pressure at 20C | Working Pressure at 250C | Burst Pressure | Bend Radius |

| 8 | 6mm | 16×1.5 | G 3/8″ | 475 bar | 285 bar | 1900 bar | 85 mm |

| 10 | 7mm | 18×1.5 | G 1/2″ | 475 bar | 285 bar | 1900 bar | 110 mm |

| 12 | 10mm | 22×1.5 | G 1/2″ | 450 bar | 270 bar | 1800 bar | 150 mm |

| 16 | 12.5mm | 26×1.5 | 3/4″ | 400 bar | 240 bar | 1600 bar | 175 mm |

| 20 | 16mm | 26×1.5 | 1″ | 300 bar | 180 bar | 1200 bar | 200 mm |

| Operating Temp | 20C | 100C | 150C | 200C | 250C |

| Multiplier | 1 | 0.95 | 0.9 | 0.83 | 0.6 |

Common Applications

– Hot Melt Systerms

– Petroleum Products

– Food Products

– Hot Oil Lines

– Chermical Transfer

– Gas Analyzer Systems

– Steam Transfer

– Water & Waste Disposal

– Bulk Transfer

– Paint Systems

– Tar & Asphalt

– Waxes; Candle making

– Adhesives

Why Use a Heated Hose:

1. The flexibility of the hose removed many alignment and machine vibration related issues.

2. Short heat-up times & uniform heat

3. Safe, economical, and long lasting