Miniature Cartridge Heater Manufacturer

1/8″ diameter, 5/32″ diameter, 3/16″ diameter, 4mm diameter

- Manufacturer

- Always On Time

- Fast, Cheap, and Reliable Shipping

- Quick Response Times (10 minutes or less)

Standard Lead Times

- 2-3 Weeks Manufacturing

- 1-3 days shipping

MPI Morheat has an extensive Stock List of Cartridge heaters available for same day shipment. MPI Morheat also manufactures custom cartridge heaters and can expedite production if needed.

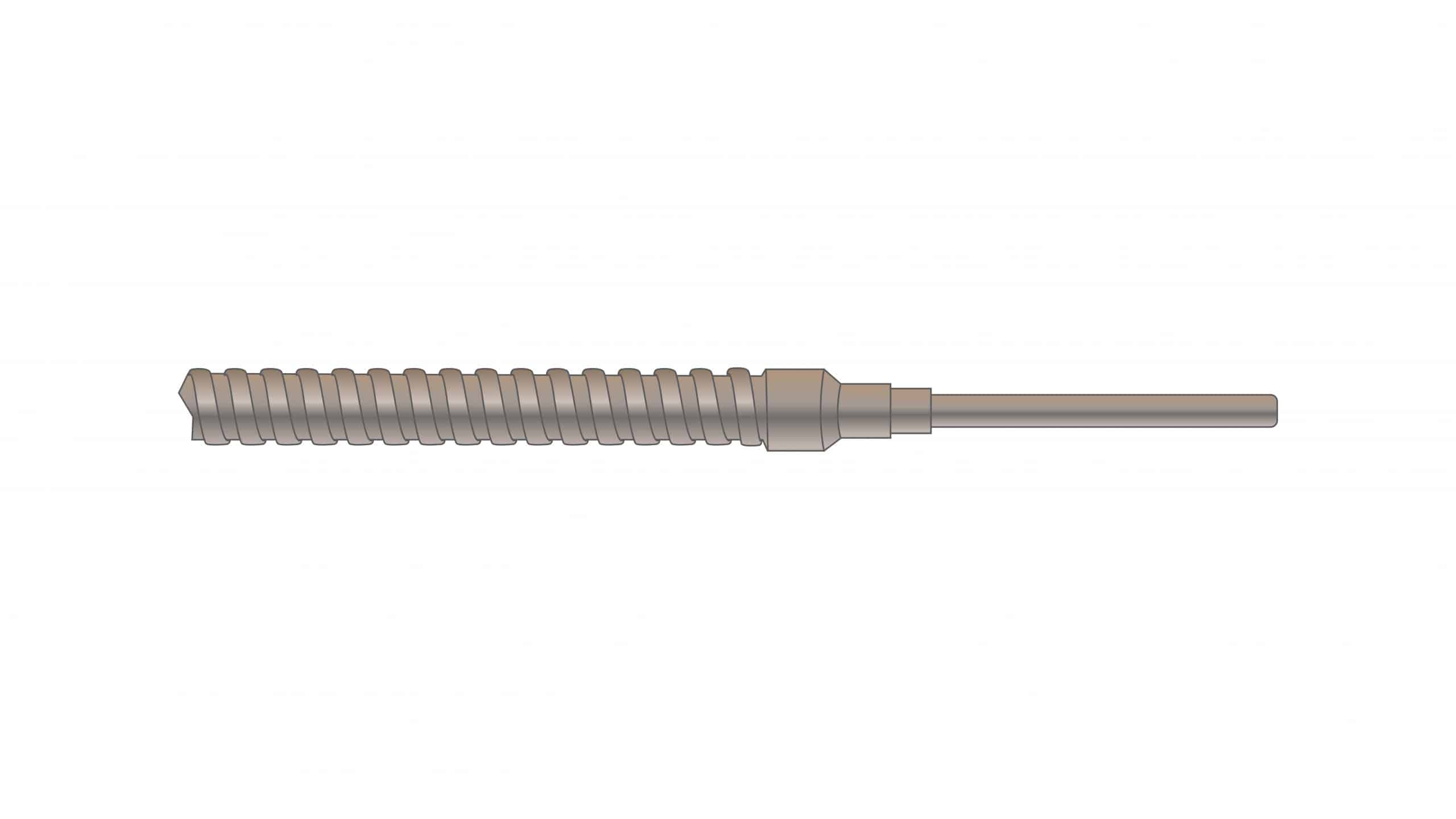

Cartridge heaters are most frequently used for heating metal parts through insertion into drilled holes. For easy installation, the heaters are made slightly undersized relative to their nominal diameter. The majority of applications do not require maximum watt/in². Using as little wattage as possible to meet process requirements will ensure maximum heater life.

Holes should be drilled and reamed, rather than drilled to the final diameter with a general purpose drill. At high watt densities, a close fit is important. The fit is the difference between the minimum diameter of the heater and maximum diameter of the hole.

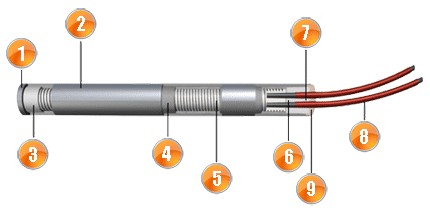

The standard sheath material is 304 Stainless Steel which provides good thermal conductivity and resistance to corrosion and scaling. The welded end disc made from the same material as the sheath provides a positive seal against moisture and other contaminants. Grade “A” Nickel-Chrome resistance wire precisely wound on a high purity magnesium oxide core places the resistance wire as close to the inside of the sheath as possible. A high purity Magnesium Oxide (MgO) powder is used to fill all remaining space inside the sheath. Heater is then swaged, which compacts the magnesium oxide grains into a solid mass.

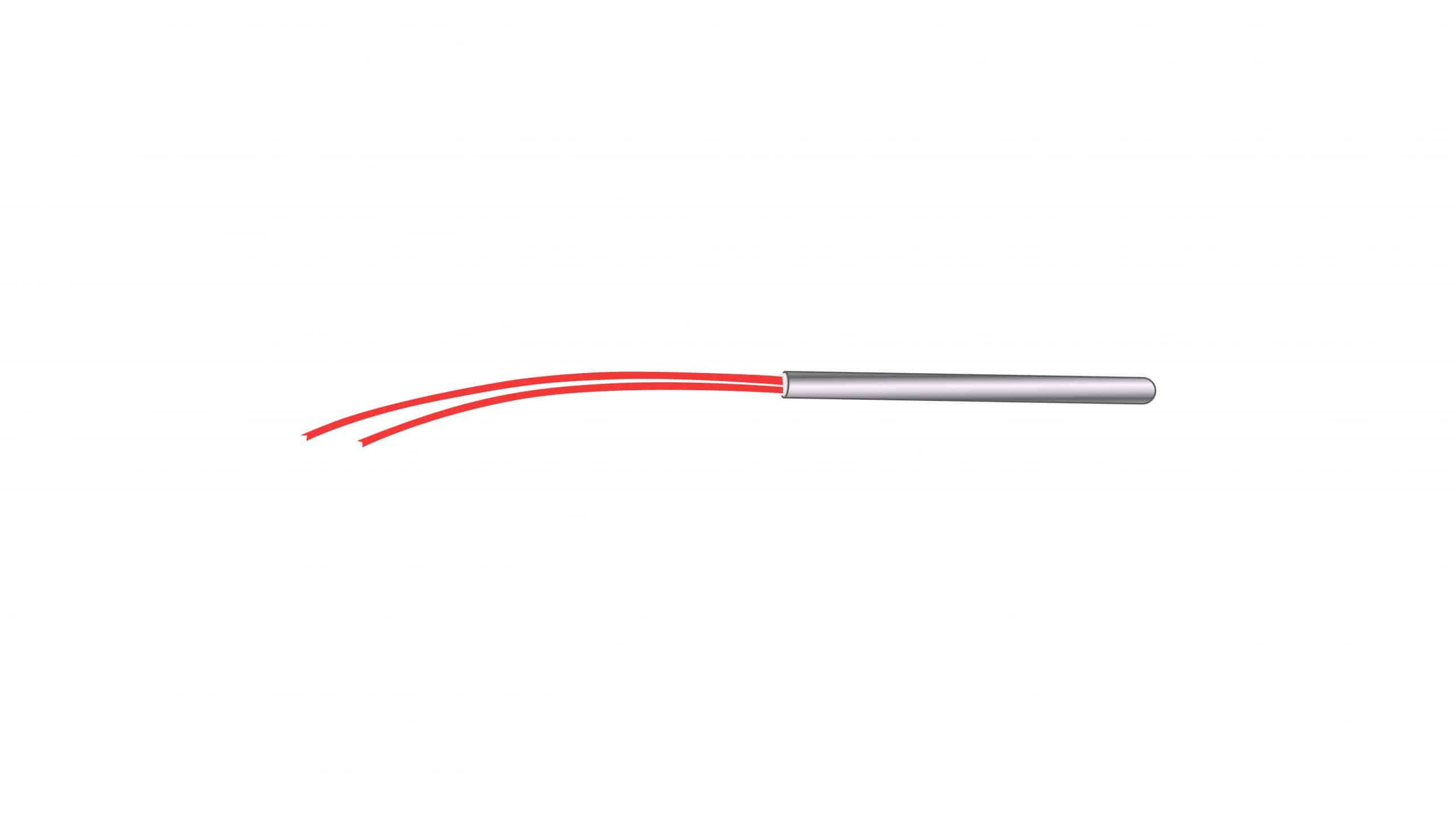

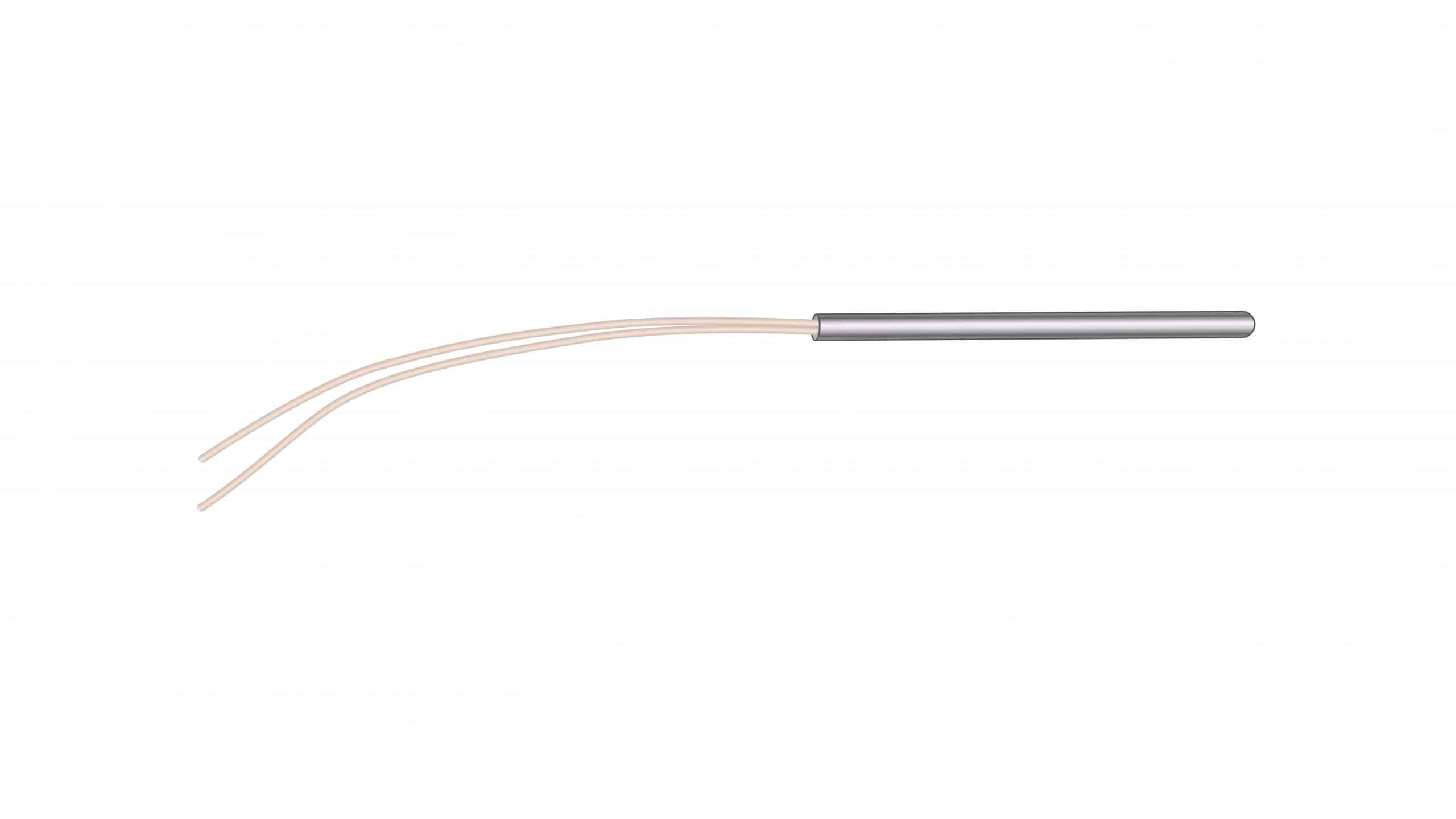

The standard termination is a Teflon® plug with Teflon® leads (Type M3) with internally connected leads that provide flexibility and allow the leads to bend sharply as they exit the heater.

| Nominal Diameter | 1/8″ | 5/32″ | 3/16″ |

| Actual Diameter | 0.122″/3.1mm | 0.153″/3.89mm | 0.184″/4.67mm |

| Tolerance | ± .002″/.051mm | ||

| Min Length | 1.25″/31.8mm | ||

| Max Length | 12″/305mm | ||

| Length Tolerance (up to 3.5″L) | ± .3/32″/2.4mm | ||

| Length Tolerance (over 3.5″L) | ± .3% of Sheath Length | ||

| Nominal Diameter | 1/8″ | 5/32″ | 3/16″ |

| Maximum Voltage | 240 | ||

| Maximum Amperage | 3 | ||

| Maximum Wattage at 120V | 360 | ||

| Maximum Wattage at 240V | 720 | ||

| Wattage Tolerance | +10,-15% | ||

| Resistance Tolerance | +15,-10% | ||