- Manufacturer

- Same Day Manufacturing Available

- CSAus Approved Heaters (UL Equivalent)

- Always On Time

- Fast, Cheap, and Reliable Shipping

- Quick Response Times (10 minutes or less)

Standard Lead Times

- 2 Weeks Manufacturing

- **Same Day Manufacturing Available**

- 1-3 days shipping

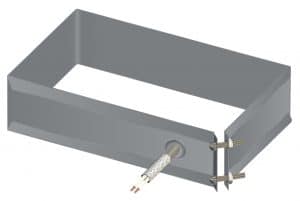

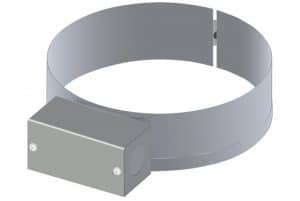

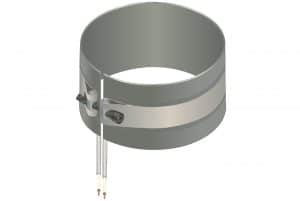

Mica Band heaters are industrial heating elements that are constructed with a mica core that is wound with wire and then shaped into a circular band. The leads are attached and the heater is enclosed in an outer sheath to complete the assembly. These heaters are unique in that they can be installed directly onto barrel heaters without the need to remove the initial heater. They also only require one set of leads or terminals, and they are made with polished precision.

Our Mica Band heaters come in many variations, each with its own unique characteristics. However, if you don’t see a variation that meets your needs, we offer customized solutions to our customers. Contact us at 416-675-7329 or email us at sales@mpimorheat.com for any questions or inquiries.

Mica Band heaters have a number of capabilities and benefits. They have a sheath temperature that can operate up to 900°F, watt densities up to 45 W/in² (7.0 W/cm²) and have CSAus (UL Equivalent) Component Recognition that is available for applications up to 900°F. Clamping straps are also available to assure efficient heat transfer. The low mass design allows for quick heat-up and fast response times.

Mica Band heaters are commonly used in a variety of industrial applications such as plastic extruders, injection molding machines, blown film dies, container pipe and tank heating, laboratory equipment, restaurant and food equipment, and pharmaceutical industries.

- Install the Mica Band Heater onto a clean surface

- Tighten the barrel nut until the screw cannot be tightened any further. If there are mutiple barrel nuts, alternate tightening each screw evenly until they cannot be tightened any further.

- Ensure the heaters is stead correctly on the barrel and tap around the circumference of the heater with a rubber mallet to ensure good, even contact.

- Power up the heater and heat the process up to operating temperature

- Mica Band Heaters will expand during the heat up process, so it is critical to re-tighten them once they reach temperature

- It is recommended to re-tighten the barrel nuts every 3-4 months

Some of the Products we have Made➟

Toronto, Canada Plant

97-170 Brockport Dr. Toronto Ontario, Canada M9W 5C8 Ph. : (416) 675-7329 (800) 817-3486 USA/CAN (800) 880-4531 MEX

- Electric Heaters & Elements

- Temperature Controllers

- Temperature & Pressure Sensors

- Cartridge Heaters

- Band Heaters

- Strip Heaters

- Coil & Cable Heaters

- Cast-In Heaters

- Flexible Heaters

- Tubular Heaters

- Screwplug & Flange Immersion Heaters

- PTFE & Metal Tank Heaters

- Infrared Heaters

- Heated Hose

- Heater Accessories

- Drum Band Heaters

- Ceramic Fiber Heater

- Duct Heaters

- Temperature Control Panel

- MT50 Series – PID Autotune Temperature Controllers

- Brainchild Temperature Controllers

- Thermocouples

- RTDs

- Melt Pressure Transducers & Transmitters

- Extruder Rupture Disks / Burst Plugs

- Linear Transducers

- Mercury Contactor Relays

- Industrial Heating Technical Info

- About MPI

- Contact Us

- Electric Heaters & Elements

- Temperature Controllers

- Temperature & Pressure Sensors

- Cartridge Heaters

- Band Heaters

- Strip Heaters

- Coil & Cable Heaters

- Cast-In Heaters

- Flexible Heaters

- Tubular Heaters

- Screwplug & Flange Immersion Heaters

- PTFE & Metal Tank Heaters

- Infrared Heaters

- Heated Hose

- Heater Accessories

- Drum Band Heaters

- Ceramic Fiber Heater

- Duct Heaters

- Temperature Control Panel

- MT50 Series – PID Autotune Temperature Controllers

- Brainchild Temperature Controllers

- Thermocouples

- RTDs

- Melt Pressure Transducers & Transmitters

- Extruder Rupture Disks / Burst Plugs

- Linear Transducers

- Mercury Contactor Relays

- Industrial Heating Technical Info

- About MPI

- Contact Us