Immersion Cartridge Heater Manufacturer

- Manufacturer

- Same Day Manufacturing Available

- CSAus Approved Heaters (UL Equivalent)

- Always On Time

- Fast, Cheap, and Reliable Shipping

- Quick Response Times (10 minutes or less)

Standard Lead Times

- 2-3 Weeks Manufacturing

- **Same Day Manufacturing Available**

- 1-3 days shipping

MPI Morheat has an extensive Stock List of Cartridge heaters available for same day shipment. MPI Morheat also manufactures custom cartridge heaters and can expedite production if needed.

Cartridge heaters are most frequently used for heating metal parts through insertion into drilled holes. For easy installation, the heaters are made slightly undersized relative to their nominal diameter. The majority of applications do not require maximum watt/in². Using as little wattage as possible to meet process requirements will ensure maximum heater life.

Holes should be drilled and reamed, rather than drilled to the final diameter with a general purpose drill. At high watt densities, a close fit is important. The fit is the difference between the minimum diameter of the heater and maximum diameter of the hole.

We can also manufacture heaters to exact diameters – ex. 0.496″ Diameter Heaters

| Diameter Sizes Available and Tolerances | |||||||||

| Sizes – Round | Sizes – Square | ||||||||

| Nom Dia | Min Dia | Max Dia | Max Amps | Max Volts | Nom Size | Min Size | Max Size | Max Amps | Max Volts |

| 1/8″ | 0.119 | 0.124 | 3.6 | 240 | 3/8″x3/8″ | 0.369 | 0.374 | 9 | 300 |

| 1/4″ | 0.244 | 0.249 | 9 | 30 | 1/2″x1/2″ | 0.494 | 0.499 | 9 | 300 |

| 6.5mm | 0.25 | 0.255 | 9 | 300 | 5/8″x5/8″ | 0.619 | 0.624 | 15 | 300 |

| 8mm | 0.309 | 0.314 | 9 | 300 | Sizes – Rectangle | ||||

| 3/8″ | 0.369 | 0.374 | 9 | 480 | Nom Size | Max Width | Max Depth | Min Watts | Max W/in |

| 10mm | 0.388 | 0.393 | 15 | 480 | 1/8″x1/4″ | 0.124 | 0.249 | 10 | 30 |

| 7/16″ | 0.432 | 0.437 | 15 | 600 | 1/8″x3/8″ | 0.124 | 0.374 | 10 | 50 |

| 12mm | 0.466 | 0.471 | 15 | 600 | 1/4″x5/8″ | 0.249 | 0.624 | 10 | 70 |

| 12.5mm | 0.486 | 0.491 | 15 | 600 | 1/4″x1″ | 0.249 | 0.999 | 10 | 100 |

| 1/2″ | 0.494 | 0.499 | 15 | 600 | |||||

| 13mm | 0.506 | 0.511 | 15 | 600 | |||||

| 17/32″ | 0.525 | 0.53 | 15 | 600 | |||||

| 14mm | 0.545 | 0.55 | 26 | 600 | |||||

| 5/8″ | 0.619 | 0.624 | 26 | 600 | |||||

| 16mm | 0.624 | 0.629 | 26 | 600 | |||||

| 17mm | 0.663 | 0.668 | 26 | 600 | |||||

| 11/16″ | 0.682 | 0.687 | 26 | 600 | |||||

| 19mm | 0.742 | 0.747 | 26 | 600 | |||||

| 3/4″ | 0.744 | 0.749 | 26 | 600 | |||||

| 20mm | 0.782 | 0.786 | 26 | 600 | |||||

| 25mm | 0.978 | 0.983 | 26 | 600 | |||||

| 1″ | 0.994 | 0.999 | 26 | 600 | |||||

- Length tolerance is +/- 3% or +/- 3/32, whichever is greater.

(*excludes disc and lead end varied formation lengths) - Camber tolerance is .025″ per foot of length. Slight camber is normally not a problem since the heater will flex enough to enter a clean hole.

- Wattage tolerance is +5%, -10%

| End Seal Options | |||||

| Type | Max Temp | Moisture Protection | Contaminant Protection | Mech. Strength | Vibration Resist. |

| Ceramic | 2500°F 1371°C | Poor | Poor | Excellent | Excellent |

| Teflon | 300°F 149°C | Excellent | Excellent | Very Good | Excellent |

| Lava | 3000°F 1649°C | Poor | Good | Good | Poor |

| Cement Potting | 1800°F 982°C | Poor | Fair | Good | Poor |

| Epoxylite Potting | 650°F 343°C | Fair | Very Good | Very Good | Excellent |

| Epoxy Potting | 265°F 129°C | Good | Good | Excellent | Excellent |

| Silicone Rubber | 500°F 260°C | Excellent | Excellent | Fair | Excellent |

| Add Ons Features | ||

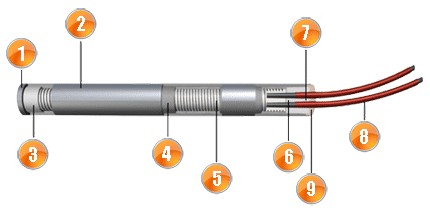

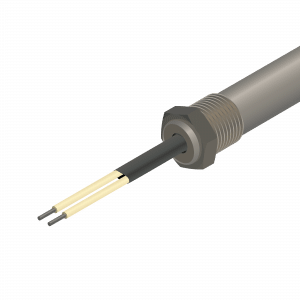

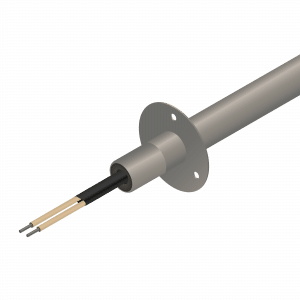

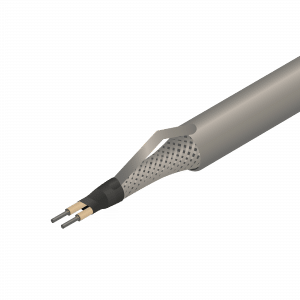

| Picture | Type | Notes |

| Stainless Steel Fittings | Single or Double-ended : 1/8″, 1/4″, 3/8″NPT 1/2″, 3/4″, 1″NPT |

| Brass Fittings | Single or Double-ended : 1/8″, 1/4″, 3/8″NPT 1/2″, 3/4″, 1″NPT |

| Flanges | Standard Stainless Steel. Flanges can be round or irregularly shaped. |

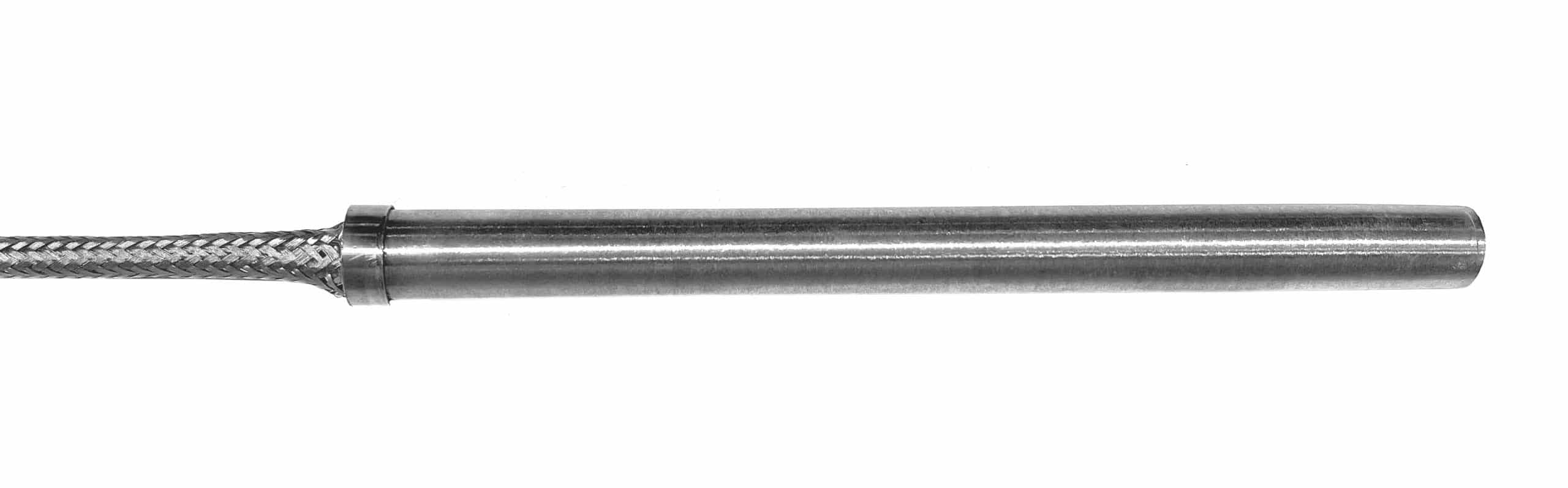

| Strain Relief | Provides extra support for leads. Great for Flexing applications |

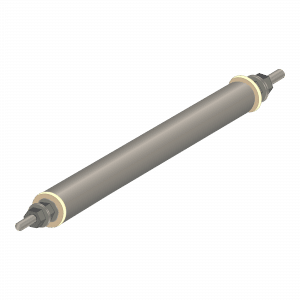

| Special Constructions | ||

| Picture | Type | Notes |

| Bent Heater | Must be bent in an unheated section |

| MultiZone or Distributed Watts | Multi Zone – Up to 3 zones Distributed Wattage – custom |

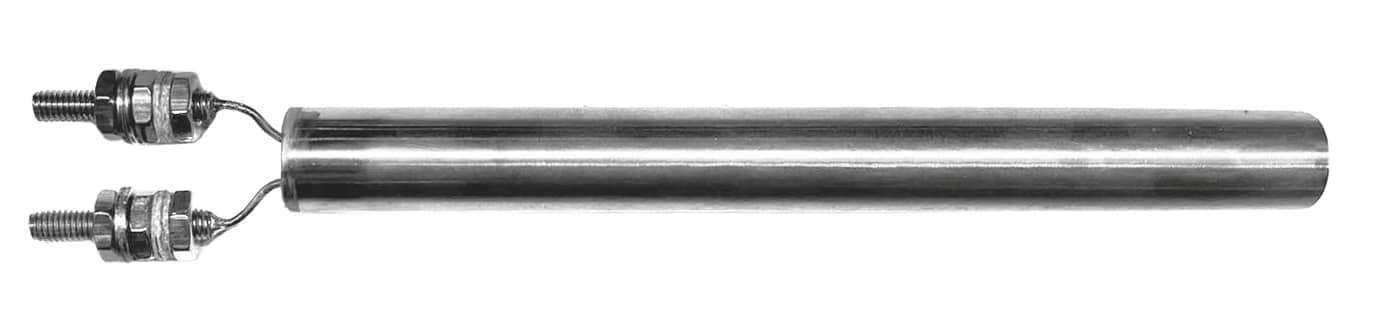

| Double Ended | Electrical Termination on Both Sides – either Lead Wires, Post terminals |

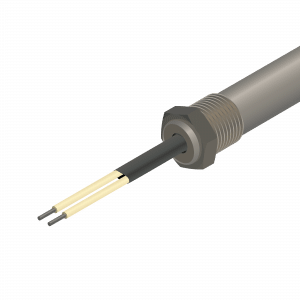

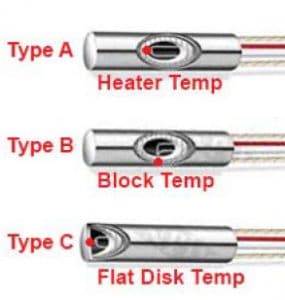

| Internal T/C | (J/K)Type A – Center Core – Heater Temperature Type B – Middle – Block Temperature Type C – End – Disk End Temperature Flat Bottom |